Mon-Sat 9.00 AM - 6.00 PM

Mon-Sat 9.00 AM - 6.00 PM Mon-Sat 9.00 AM - 6.00 PM

Mon-Sat 9.00 AM - 6.00 PM

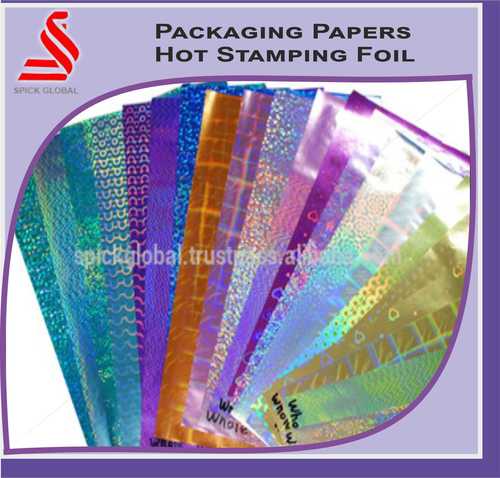

Hot Stamping Foil Packaging Foil Papers

Product Details:

- Pattern Plain, Holographic, Striped or Custom Patterns

- Shape Roll / Sheet

- Features Scratch Resistant, Durable, High Shine, Premium Finish

- Adhesive Type Heat Activated Adhesive

- Print Type Foil Printing

- Printing Method Hot Stamping

- Usage & Applications Used in Cosmetics, Food Packaging, Pharmaceuticals, Gift Wrapping

- Click to View more

Hot Stamping Foil Packaging Foil Papers Price And Quantity

- USD ($)

- depends Piece

- 12 - 24 Months in Proper Storage

- RoHS and REACH compliant

- Cool, Dry Place Away from Sunlight

- Non-toxic, Safe for Consumer Goods

- 1 Inch or 3 Inch

- 90C to 130C (hot stamping conditions)

- Cold or Hot Peel, depending on requirement

- <3% under Standard Stamping Conditions

- Logo, Width, Color, Pattern Available on Request

- 95%

- Suitable for Paper, Plastic, Leather, and Textile Surfaces

- High Coverage

- Silicone Coated

- 100 Rolls

Hot Stamping Foil Packaging Foil Papers Product Specifications

- Glossy and Metallic

- Multiple Colors (Gold, Silver, Red, Blue etc.)

- Plain, Holographic, Striped or Custom Patterns

- Thermo-adhesive

- Roll / Sheet

- 120 Meters / roll (Customizable)

- 12 Microns to 25 Microns

- Scratch Resistant, Durable, High Shine, Premium Finish

- Packaging Decoration, Branding, Labelling

- Custom Printed

- Heat Activated Adhesive

- Foil Printing

- Hot Stamping

- Used in Cosmetics, Food Packaging, Pharmaceuticals, Gift Wrapping

- Hot Stamping Foil

- Mirror/Glossy/Matte

- Polyester (PET) Film

- Standard 64cm (Customizable)

- Yes

- 12 - 24 Months in Proper Storage

- RoHS and REACH compliant

- Cool, Dry Place Away from Sunlight

- Non-toxic, Safe for Consumer Goods

- 1 Inch or 3 Inch

- 90C to 130C (hot stamping conditions)

- Cold or Hot Peel, depending on requirement

- <3% under Standard Stamping Conditions

- Logo, Width, Color, Pattern Available on Request

- 95%

- Suitable for Paper, Plastic, Leather, and Textile Surfaces

- High Coverage

- Silicone Coated

- 100 Rolls

Hot Stamping Foil Packaging Foil Papers Trade Information

- New Delhi, India

- 100000 Piece Per Day

- Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- PACKAGING DETAILS- Holograms labels-sheets 6.5" onwards to 40" die cut to sizes shapes and rolls on paper core 3"/6" id cores. Holographic Films -1"-6" core wound upto 36000 meters. Overlays holographic- Single and six overlays to sheets as well as custom sized. Holographic ribbons -As per Machine/Model wound on Plastic/Paper cores compatible. Holographic Foils - Rolls on 1/3/6 inch core from 5mm to 1280mm widths x 100-12000 meters All standard Export Worthy packing even for local indian Despatch .Custom and Contract Packing available too Packaged Standard Cartons and Euro Pallets in biodegradable moisture proof Packing for despatch Worldwide via Fedex/DHL/UPS door to door as well as AirShipments via airlines and Sea Shipments via less than Container loads to High Cube 40 FCl.Export licensed company with 90 countries WorldWide covered since 2003.

- Australia, North America, Eastern Europe, South America, Africa, Western Europe, Central America, Middle East, Asia

- All India

- ISO 9001 2015

Product Description

We are Leading Manufacturer, Exporter, Importer, Distributor and Supplier of Holographic wide web film in both PET and BOPP. Holographic Wide Web Films provide 100% security to the products against the threat of counterfeiting and duplicity by making them completely secure.

Holographic Film are specially designed and manufactured using premium quality raw material and sophisticated printing technology for extensive utilization in packaging industry. Its combats the risk of duplicity & increases the aesthetics of products. This is very useful for flexible packaging, laminations, printing, labels and gift wrappings etc.

Main Features of Specialty Holographic Films

- Attractive looks with Optimum clarity

- Shine and Glossy with high brightness high gloss holographic effects

- Superior bonding strength Heat resistant, water proof

- Lot of Different colors and patterns, Plain, light beam and pattern. Many designs available for selection and customers designs welcome

- Exellent print possible using these films via UV offset, Screen print, Flexo and gravure printing.

- .Used for toiletries, Tobacco, Flexible packaging, Printing, wine boxes, Gift boxes, Books, Magazines, Boxes, Printed products and other paper products laminating. Suitable for high grade imitation pseudo carton laminating.

Technical Description of Holographic Wide Web Film

|

Material |

BOPP, PET |

|

Types |

Transparent, Metalized, Color Coated. |

|

Thickness |

From 12micron to 150micron |

|

Width |

10mm to 1650mm |

|

Roll Length |

1000m-7000m |

|

Design |

Around 150 patterns. Your design is welcome |

|

Color Coating |

Red, Green, Purple, Gold, Royal Blue, Sky Blue, Pink, Dark Pink, Silver |

Exports to:

USA, EUROPE, ASIA, AUSTRALIA, SOUTH AMERICA, NEWYORK, UK, LONDON, UAE, DUBAI, GERMANY, BELGIUM, NETHERLAND, FRANCE, SPAIN, CANADA, AUSTRALIA, NEWZEALAND, RUSSIA, UKRAINE, BELARUS, MOLDOVA, LATVIA, LITHUANIA, ITALY, GREECE, POLAND, ROMANIA, HUNGARY, SLOVAKIA, AUSTRIA, BOSNIA & HERZEGOVINA, BULGARIA, CROATIA, CZECH, REPUBLIC, DENMARK, ESTONIA, FINLAND, ARMENIA, TURKEY, GEORGIA, ICELAND, IRELAND, MACEDONIA, MONTENEGRO, NORWAY, PORTUGAL, SLOVAKIA, SLOVENIA, SWITZERLAND, SWEDEN, IRAN, IRAQ, JORDON, ISRAEL, PALESTINE, SAUDI ARABIA, QATAR, OMAN, BAHRAIN, KUWAIT, EGYPT, KOREA, JAPAN, VIETNAM, THAILAND, HONG KONG, CHINA, INDONESIA, MALAYSIA, SINGAPORE , PANAMA, COLOMBIA, CHILE, PERU, BOLIVIA, ARGENTINA, BRAZIL, BOLIVIA, ECUADOR, PARAGUAY, URUGUAY, VENEZUELA, MORROCO, TUNSIA, UGANDA , LIBERIA, GHANA, ALGERIA, ANGOLA, SOUTH AFRICA, KENYA, NIGERIA, CONGO, SUDAN, MOZAMBIQUE, TANZANIA, ZAMBIA etc.

Premium Decoration and Branding

Enhance your product packaging with high-shine, scratch-resistant hot stamping foils. Designed for premium appearance and high opacity, these foils are suitable for diverse applications such as branding, labelling, and decorative enhancement across multiple industries. Enjoy flexibility in design with options for custom widths, colors, patterns, and printed logos.

Reliable Performance and Safe Use

Our foils guarantee quality with exceptional transfer efficiency (95%) and minimal shrinkage. Manufactured using non-toxic, RoHS and REACH compliant materials, they ensure safety for consumer products. The silicone-coated release liner and heat-activated adhesive allow consistent results under standard hot stamping conditions (90C to 130C).

Broad Compatibility and Easy Application

These hot stamping foils are engineered for compatibility with paper, plastics, textiles, and leathers. Storage is simplejust keep rolls in a cool, dry place out of sunlight for peak performance over 12 to 24 months. Both hot and cold peel application options are available, making them adaptable for various production needs.

FAQs of Hot Stamping Foil Packaging Foil Papers:

Q: How do I use Hot Stamping Foil Packaging Foil Papers for best results?

A: To achieve optimal results, set your hot stamping machine to operate within the temperature range of 90C to 130C. Select a cold or hot peel method depending on your projects needs. Ensure the surface is clean and dry, and align the foil for even coverage before applying heat and pressure.Q: What surfaces are compatible with these hot stamping foils?

A: These foils are suitable for use on paper, plastic, leather, and textile surfaces, making them versatile for packaging, branding, labels, and decorative applications in various industries.Q: When should I use hot peel versus cold peel during the stamping process?

A: Choose hot peel for applications where immediate release after stamping is needed, typically for speed and certain surface effects. Cold peel is preferred when better adhesion and precise edge definition are desired. Your choice depends on the material and finish required.Q: Where should I store unused foil rolls to maintain quality?

A: Store unused rolls in a cool, dry environment away from direct sunlight. Proper storage conditions help preserve shelf life (1224 months) and maintain high transfer efficiency and appearance.Q: What customization options are available for these foils?

A: We offer extensive customization including logo printing, color, pattern (plain, holographic, striped, custom), width, length, and surface finish (glossy, matte, or mirror). Please contact us with your specifications.Q: What are the benefits of using hot stamping foil for packaging and branding?

A: Hot stamping foils provide a luxurious, high-shine finish that enhances visual appeal and brand recognition. They are durable, scratch-resistant, waterproof, and ensure safe usage thanks to their non-toxic, RoHS and REACH compliant construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Get a Quote

Get a Quote

Call Me Free

Call Me Free